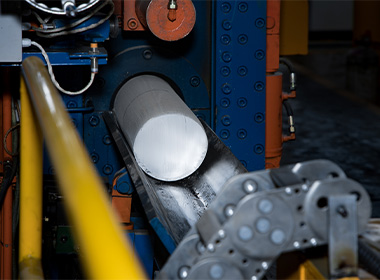

No matter how specialized and demanding your application and requirements are, we adapt our systems flexibly to your specific needs.

Whether construction components, medical products, consumer goods, whether extrusion or CNC production - with its machine vision systems for 100% surface inspection and dimension measurement, FINE provides a tailor-made inspection solution for any application. Thus, saving your resources, ensuring utmost quality and securing your success.